From Sprockets to Idlers: The Full Option for Reputable Undercarriage Parts

From Sprockets to Idlers: The Full Option for Reputable Undercarriage Parts

Blog Article

Important Overview to Undercarriage Parts for Heavy Devices

When it pertains to hefty equipment, the undercarriage plays a crucial duty in making sure smooth and efficient operations. Comprehending the elaborate details of undercarriage parts is important for making the most of the life-span and performance of your equipment. From track chains to rollers and idlers, each element adds to the general performance of the tools. Exploring the specifics of gears and various other undercarriage components gives vital insights right into maintenance techniques that can dramatically influence the longevity of your heavy machinery. By understanding the significance of these components and their upkeep needs, drivers can optimize the efficiency and durability of their tools, ultimately leading to set you back savings and improved operational efficiency.

Relevance of Undercarriage Components

Understanding the vital role that undercarriage components play in the efficiency and long life of heavy tools is extremely important for reliable upkeep and operation - undercarriage parts. The undercarriage components form the foundation on which the entire machine runs, sustaining the weight of the devices, offering security, and soaking up shock lots throughout operation. A properly maintained undercarriage not just makes sure smooth operation but likewise adds substantially to lowering downtime and repair expenses

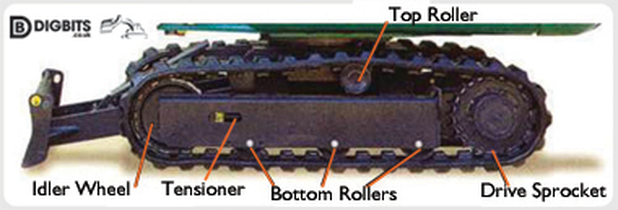

The undercarriage includes numerous vital parts such as track chains, track shoes, sprockets, idlers, rollers, and track structures. Each of these components plays an important function in the total capability of the tools. As an example, the track chains and track footwear assist in offering grip and support, while the idlers and gears help in driving the tracks efficiently. Normal evaluation, prompt upkeep, and replacement of damaged undercarriage parts are vital to stop failures and make the most of the lifespan of the hefty devices. Basically, purchasing top quality undercarriage components and guaranteeing their proper care is vital for ideal performance and resilience of heavy machinery.

Kinds Of Track Chains

Track chains are important components of heavy devices undercarriages, providing the required grip and assistance for efficient operation. There are mainly 2 types of track chains used in heavy tools: secured and oiled track chains (SALT) and completely dry track chains.

Function of Rollers and Idlers

Rollers and idlers play an important role in sustaining and directing the track chains of hefty tools undercarriages, adding to the overall security and effectiveness of the machinery. Idlers, on the other hand, overview the track chain and assistance preserve appropriate tension throughout the undercarriage system.

Together, rollers and idlers operate in harmony to ensure that the track chain stays in area, even on rough terrain, improving the equipment's efficiency and longevity. Proper maintenance and regular assessment of rollers and idlers are necessary to avoid premature wear and prospective break downs, ultimately taking full advantage of the effectiveness and life expectancy of hefty tools undercarriages.

Recognizing Gears

One critical aspect of gears is making certain appropriate positioning and stress to stop premature wear and damage. Misaligned sprockets can cause unequal endure the track chain, leading to lowered effectiveness and prospective safety threats. Routine upkeep and evaluation of sprockets are necessary to determine any type of indications of wear or imbalance without delay.

In addition, sprockets are available in different dimensions and tooth configurations, relying on the details hefty devices and its intended use. Appropriate selection of sprockets based upon the tools's specs is vital to make certain optimum efficiency and longevity of the undercarriage system. Understanding the function of sprockets and their maintenance needs is important for making the most of the efficiency and lifespan of heavy equipment undercarriages.

Upkeep Tips for Durability

To make sure the extended durability and optimal capability of hefty devices undercarriages, thorough upkeep methods are vital. On a regular basis examining undercarriage components such as track footwear, rollers, idlers, and sprockets for wear and tear is vital. Appropriate track stress adjustment is also crucial for lowering premature wear on undercarriage parts.

Final Thought

Finally, undercarriage components are vital parts for heavy equipment, playing essential functions in preserving stability and capability. Understanding the different kinds of track chains, idlers, rollers, and sprockets is very important for proper upkeep and long life of the equipment. By adhering to maintenance suggestions and on a regular basis examining and replacing used parts, operators can guarantee the ideal performance and effectiveness of their heavy machinery. Correct treatment and interest to undercarriage components are essential to making the most of tools lifespan and look at this site productivity.

The undercarriage consists of different important parts such as track chains, track hop over to these guys footwear, sprockets, idlers, rollers, and track frameworks. The track chains and track shoes help in offering traction and support, while the gears and idlers aid in driving the tracks smoothly (undercarriage parts). There are mostly 2 types of track chains made use of in hefty devices: sealed and lubed track chains (SALT) and completely dry track chains. Proper selection and upkeep of track chains are vital to make certain the general performance and long life of heavy equipment undercarriages

Gears are essential elements of hefty devices undercarriages, liable for transferring power from the equipment to the track chain.

Report this page